Testing Services – Fuel Systems

Fuel Systems Testing

Carbon Canister Testing

Vehicle Hose Testing

Permeation Testing

Fuel systems manufacturers must have confidence in the reliability and durability of their fuel systemscomponents to stay competitive. Stringent quality and safety requirements mandate these systems meet specific requirements throughout the entire product lifecycle, from development to validation.

We work with many automotive OEM’s and Tier 1 customers to provide robust and efficient fuel systems components testing that help them meet their requirements and the test specifications that are set within relevant standards.

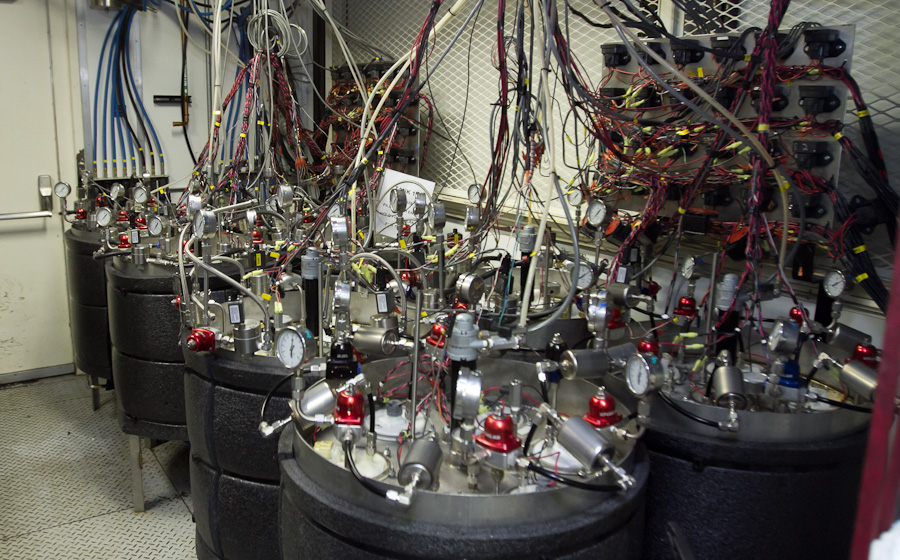

Sterling Performance is a leader in the fuel system testing of fuel systems for the transportation industry, covering a wide range of automotive and military applications. The components we test include fuel hose testing and connectors, coolant pump testing, EV coolant pump testing, fuel pump testing, fuel module testing, coolant hose testing, fluid hose testing, automotive hose testing, filters, filler caps, injectors, and tanks.

Fuel system components that fail to meet industry standards and requirements can cost millions in product recalls and erode consumer confidence. Sterling’s fuel system components testing gives you the assurance that the components in your vehicles are safe, function as designed and are compliant.

Additional Fuel Testing Capabilities

-

Butane & Gasoline Working Capacity

-

Canister Aging & Durability

-

Fuel Caps & Filler Neck Testing

-

Fuel Filter Testing Exposure Testing

-

Fuel Pressure Switches / Regulators Testing

-

Fuel Pump Endurance Testing

-

Fuel Pump Performance Testing

-

Fuel Rail Testing Endurance & Exposure Testing

-

Fuel Line Testing

-

Quick Connect Testing

-

Fuel Soak, Hot or Cold Temperature Cycling

-

Fuel Tank Aging and Performance Testing

-

Fuel Vapor Exposure

-

Helium Leak Testing

-

Integrated Air Fuel module (IAFM) Validation Testing

-

Onboard Refueling Vapor Recovery (ORVR)

-

SHED testing, Mini & Micro

For more information about our fuel components testing services, or to request a quote, contact us today.

We are an ISO/IEC 17025 accredited facility offering a wide range of test and analysis services. We specialize in fuels and fluids testing for the transportation industry. From DV and PV testing to more custom requirements on systems and components, we have the expertise to deliver quality results on time and within budget. Located in Milford, Michigan – Sterling Performance provides development, durability, and validation testing of fuel systems and components for automotive, marine, off-road, and industrial manufacturers and suppliers, as well as vibration, environmental, engine dynamometer service, and materials testing.

See what other industries we serve. our 34,000+ square foot facility houses everything needed to provide a variety of testing lab services, from automotive, OEM, Marine, small and industrial engines.

It is our goal to:

- Be recognized as the top Permeation Testing Facility in the state.

- Become a growing partner in EV battery testing, battery testing, and battery pack testing

- Continue to grow and expand our testing capabilities.

- Accommodate the upcoming, futuristic technological needs of our customers

- Build a positive rapport with all our customers and encourage customer satisfaction, loyalty and repeatability by providing accurate precision test results.

Other Services

Carbon canister testing

Complete Carbon Canister Testing using the guidelines set forth by EPA & CARB

Battery Testing

Battery Cell Testing, Battery Pack Testing on all types of batteries, including EV battery testing.

Hose Testing

All forms of hoses, assemblies, & connectors. Fuel hose testing, coolant hose testing, fluid hose testing, automotive hose testing.

Pump Testing

Any Fuels or Fluids, Hydraulic oils, and water, Including EV cooling pump testing for EV’s & PHEV’s.

Evaporative Emissions

Evaporative emissions testing utilizing SHED testing methods.

Thermal Shock Testing

We can simulate virtually any environmental condition with our multiple thermal & humidity chambers.

Fuel System Components

Anything related to the fuel delivery system, pumps, injectors, lines, tanks, valves, fill pipes, rails.

Fluids Testing

From Coolants to solvents to oils, filters, hoses, & plastic parts.

Vibration Testing/NVH Testing

Vibration, shock, and acceleration testing can be done individually or in conjunction with temperature, pressure, flow.