Energy Storage System Testing / Battery Testing

Energy Storage System Testing – Lithium Ion Battery Testing Services

Electric Vehicle Battery Testing (EV) and Hybrid Electric Vehicle Battery Testing (HEV)

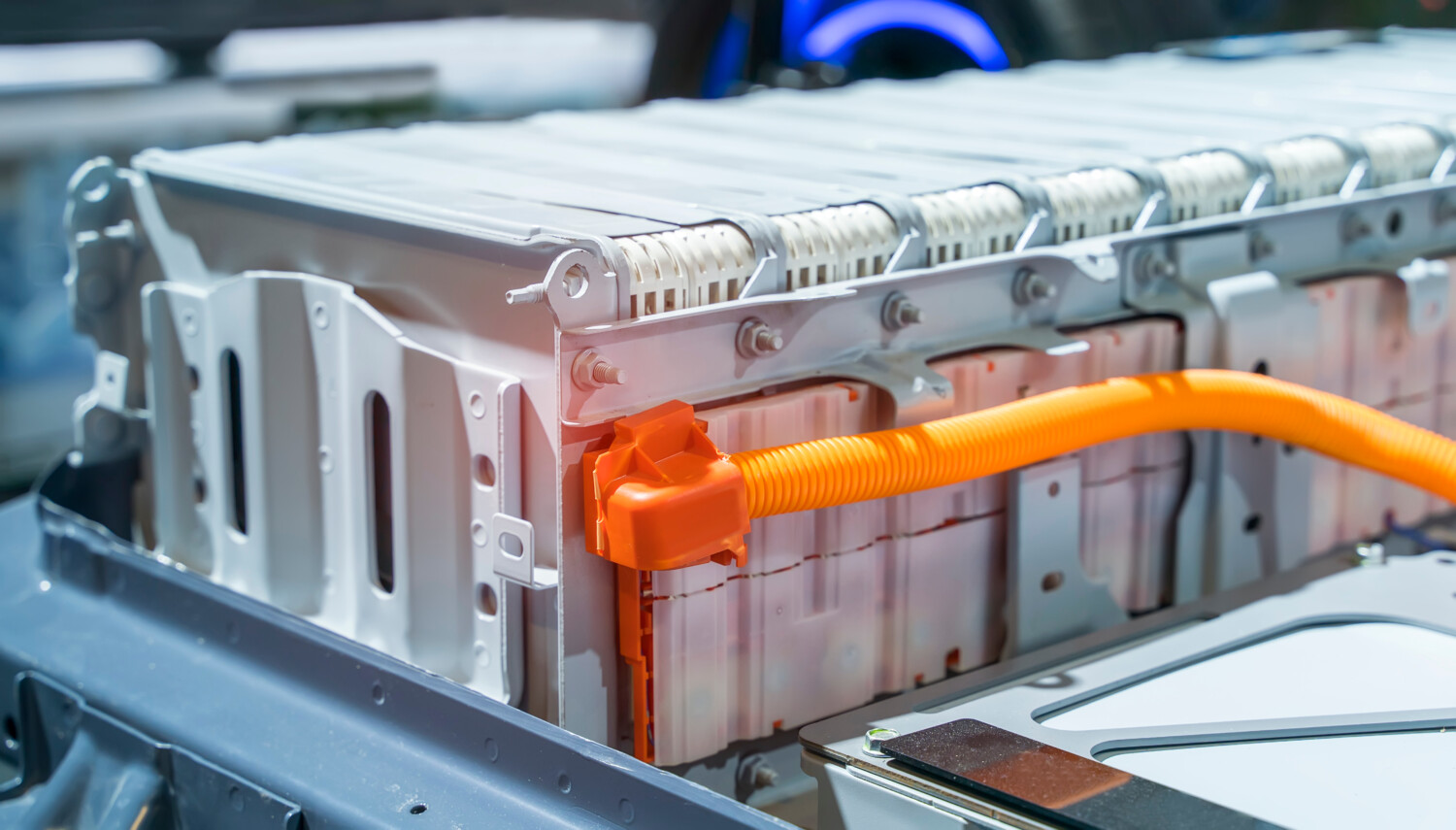

Energy Storage System testing include EV battery testing and HEV battery testing- As the transportation industry evolves, new technologies like PHEV’s and electric vehicles will require extensive battery testing. Sterling can perform validation via Lithium Ion Battery Testing (Li-ion) and Nickel Metal Hydride Battery testing (Ni-MH). Complete battery testing services: Battery cell testing, Battery module Testing, and Battery pack testing, to ensure these components not only perform as designed but do it safely.

From Lifetime verification of battery systems to environmental simulation, we can perform energy storage system testing under virtually any condition. Our state-of-the-art facility has the newest cyclers chambers and testing equipment to handle almost any type of EV battery testing or HEV battery testing requirement, with the capacity to run low voltage cells to high voltage packs.

For those projects that have more challenging requirements or custom setups, our team of battery testing experts can work with you to design and implement protocols that simulate normal and extreme operating conditions.

Hybrid Electric Vehicle Battery and Electric Vehicle Battery Test Services

Sterling can provide a comprehensive range of battery testing services to ensure your batteries perform as intended.

Some of the tests we provide are:

- EV battery testing

- Battery Cell cycling

- Battery Module & Battery pack cycling

- Charge/discharge cycle durability

- Drive cycle testing

- Pulse power testing

- Shock and vibration

- Thermal battery propagation testing

- Battery nail penetration testing

- Thermal cycling

- Water Immersion

- Drop Testing

- CAN communication and control

Battery Recycling

Used batteries have been a problem for decades from both household and industrial waste perspectives. While battery technology has changed a lot, even the most advanced rechargeable lithium-ion batteries may still contain materials that are considered hazardous. Unlike other materials, these batteries can’t be reused directly, so recycling is the only viable solution. In addition, lithium battery recycling reduces the need for new mineral extraction, which is always a win for the environment. Given that, proper handling and disposal of Lithium-Ion batteries is crucial. Sterling Battery can be your partner in a recycling program. We will arrange to pick up your batteries, recycle the usable materials and dispose of the remaining items. Contact us today to learn more about how we can help.

Inspection & Failure Analysis

A battery failure analysis provides you with insights and recommendations to help prevent future incidents whether it is a failure, or the battery is not performing as expected. Our skilled technicians will inspect and evaluate your battery to determine the root cause of the issue and provide detailed reporting on our findings. This helps to prevent future failures and provides insight for improvements.

Whether battery cells, protection circuits, battery-management systems, modules or battery packs, our ISO/IEC 17025 accredited lab can test your products against OEM specifications and established standards. For more information or to request a quote, contact us today.

Other Services

Carbon canister testing

Complete Carbon Canister Testing using the guidelines set forth by EPA & CARB

Battery Testing

Battery Cell Testing, Battery Pack Testing on all types of batteries, including EV battery testing.

Hose Testing

All forms of hoses, assemblies, & connectors. Fuel hose testing, coolant hose testing, fluid hose testing, automotive hose testing.

Pump Testing

Any Fuels or Fluids, Hydraulic oils, and water, Including EV cooling pump testing for EV’s & PHEV’s.

Evaporative Emissions

Evaporative emissions testing utilizing SHED testing methods.

Thermal Shock Testing

We can simulate virtually any environmental condition with our multiple thermal & humidity chambers.

Fuel System Components

Anything related to the fuel delivery system, pumps, injectors, lines, tanks, valves, fill pipes, rails.

Fluids Testing

From Coolants to solvents to oils, filters, hoses, & plastic parts.

Vibration Testing/NVH Testing

Vibration, shock, and acceleration testing can be done individually or in conjunction with temperature, pressure, flow.